Why Is Starch A Polymer

Influence of Starch Limerick and Molecular Weight on Physicochemical Properties of Biodegradable Films

Chemic Engineering Department, Academy of Alicante, Apartado 99, 03080 Alicante, Spain

*

Author to whom correspondence should exist addressed.

Received: 29 May 2019 / Accepted: 24 June 2019 / Published: 26 June 2019

Abstract

Thermoplastic starch (TPS) films are considered one of the nigh promising alternatives for replacing synthetic polymers in the packaging field due to the starch biodegradability, low cost, and abundant availability. Even so, starch granule composition, expressed in terms of amylose content and phosphate monoesters, and molecular weight of starch clearly affects some motion-picture show backdrop. In this contribution, biodegradable TPS films fabricated from potato, corn, wheat, and rice starch were prepared using the casting technique. The upshot of the grain structure of each starch on microstructure, transparency, hydration properties, crystallinity, and mechanical properties of the films, was evaluated. Potato starch films were the most transparent and corn starch films the most opaque. All the films had homogeneous internal structures—highly amorphous and with no pores, both of which point to a practiced starch gelatinization process. The maximum tensile strength (4.48–8.xiv MPa), elongation at intermission (35.41–100.34%), and Young'due south modulus (116.42–294.98 MPa) of the TPS films were clearly influenced past the amylose content, molecular weight, and crystallinity of the film. In this respect, wheat and corn starch films, are the most resistant and least stretchable, while rice starch films are the most extensible but to the lowest degree resistant. These findings show that all the studied starches can exist considered suitable for manufacturing resistant and flexible films with similar properties to those of synthetic low-density polyethylene (LDPE), by a simple and environmentally-friendly process.

1. Introduction

Approximately 40% of food packaging is made of plastic materials [1]. During the last decades, the use of petroleum-based plastics such as depression-density polyethylene (LDPE) for this purpose has been highly intensive. However, due to dwindling petroleum resources, the extensive use of 1-use packaging materials, and the severe pollution issues related with their recycling, the development of renewable and environmentally-friendly polymers has go a priority business concern [2,3,4]. In an effort to solve this trouble, biopolymers such as starch and its derivatives (polylactic acrid, etc.), cellulose, collagen, and chitosan, take been considered as alternatives because they are abundant, inexpensive, and biodegradable [1,3,5,6]. Of these, starch is probably the most promising option because it can be readily cast into thermoplastic starch (TPS) films, which are odorless, colorless, transparent, and of very depression oxygen permeability [7]. In addition, starch is widely produced in industry, which is an reward for its use in food packaging [8]. Starch is a sugar polymer composed of two macromolecules: amylose, a linear polysaccharide with an average molecular mass of xfive one thousand·mol−one; and amylopectin, a branching polysaccharide with an average molecular mass of 10half-dozen–x7 g·mol−ane. Hydrogen bonds hold the starch bondage together, making information technology insoluble in cold water. In order to obtain a TPS motion-picture show, starch granules must exist gelatinized with a plasticizer in an excess of h2o at temperatures lower than 100 °C. Commonly used plasticizers are monosaccharides, disaccharides, oligosaccharides (glucose, fructose), and polyols (glycerol, sorbitol). In this way, hydrogen bonds are formed between the plasticizer and the starch in an irreversible gelatinization process.

Starch tin can be obtained from a great variety of botanical species, which determines the compound's grain size, size distribution, shape, amylose/amylopectin ratio, molecular weight, and phosphate monoester content. Corn, wheat, potato, and rice starch are the about mutual starch sources, representing 84%, seven%, four%, and 1% of world product, respectively [nine]. The starches have unlike pic-forming backdrop, and the chemical, physical, and mechanical backdrop of the TPS films obtained from them may vary widely [eight]. Few studies accept compared the properties and structures of TPS films obtained by casting using dissimilar starches [8,9,x] and discrepancies be with regard to the tensile properties, microstructure, and degree of plasticization of the films. To the best of our cognition, this is the first time that a systematic comparative study has been made of starch grain label and of the microstructure, crystallinity, and mechanical properties of the TPS films obtained from potato, corn, wheat, and rice starch. In addition, this is the first fourth dimension that the backdrop of TPS films obtained from the in a higher place-mentioned starches have been correlated with the starch granule limerick (amylose and phosphate monoester contents) and molecular weight of the starch grains. This work, therefore, should contribute to a better understanding of the properties of biodegradable TPS films obtained from tuber (potato) and cereal (corn, wheat and rice) starches, thereby contributing to their successful awarding in the packaging industry.

The aim of this piece of work has been to produce biodegradable TPS films from four different starch sources (potato, corn, wheat, and rice) by the casting technique, using glycerol as plasticizer (33 wt % on starch basis) and to compare their properties. 3 sub-objectives are proposed: (i) to narrate the starch grains in terms of their molecular weight, microstructure, size distribution, amylose, phosphate monoester contents, and humidity; (ii) to characterize the TPS films in terms of their hydration backdrop, migration into food simulants, microstructure, crystallinity, and tensile properties; and (iii) when possible, to establish possible relationships between the starch granule composition and molecular weight of each starch and the subsequent film properties.

2. Materials and Methods

ii.i. Materials

Corn starch (24.eight% amylose, 0.020% phosphorus content, eleven% moisture content), wheat starch (24.5% amylose, 0.038% phosphorus content, 9.6% moisture content) and rice starch (xvi.9% amylose, 0.030% phosphorus content, nine.two% moisture content) were purchased from Sigma-Aldrich (Madrid, Spain). Potato starch (xx.5% amylose, 0.043% phosphorus content, 15.1% moisture content) was provided by Across Organics (Geel, Belgium), and the plasticizer glycerol was supplied past Fisher Chemical (Geel, Kingdom of belgium). All chemicals were used without further purification.

2.2. Starch Grains Characterization

The morphology and particle size of the iv starches were determined by Scanning Electron Microscopy (SEM) and laser diffraction. The shape of the starch grains was observed by SEM (Hitachi, model S3000N, Tokyo, Nippon) with an accelerating potential of 15 kV. The particle size assay was carried out by laser diffraction (Malvern Instruments, model 2000, Worcestershire, Uk).

The Megazyme amylose/amylopectin assay process, using the commercial kit, was followed to quantify the amylose content of the starches. Determining phosphorus content was conducted with an inductively coupled plasma mass spectrometer (ICP-MS, Agilent 7700x, Agilent Technologies, Waldbronn, Germany). Gel Permeation Chromatography (GPC) coupled with Multi Angle Light Scattering (MALS) was used to determine the weight-boilerplate molecular weight of the starches. A Size-exclusion Chromatographer (SECurity 1260, Polymer Standard Service, Mainz, Deutschland) with double detection (MALS and refractive index) was employed. The mobile stage was DMSO with 0.1 M LiCl. A certain amount of each sample (≈20 mg) was exactly weighed and added to a defined book of mobile phase. After that, the samples were dissolved at lxxx °C. All solutions were filtered through a 1 µm filter before beingness injected into the GPC precolumn (PSS-Suprema, 10 μm, Baby-sit, ID 8.0 mm × 50 mm) and analytical cavalcade (PSS-Suprema, 10 μm, 10,000 Å, ID 8.0 mm × 300 mm). The cavalcade temperature was controlled at 80 °C and the flow charge per unit was 0.3 mL/min. The weight-average molecular weight of the starch samples was calculated using the WinGPC UniChrom software version eight.3 (Polymer Standard Service, Mainz, Germany).

The wet content of the starches was determined past their loss of weight after drying in an oven for 5 h at 110 °C. Crystallinity of the starch grains was studied by X-ray diffraction on a Bruker diffractometer (D8-Advance model, Ettlingen, Germany) equipped with a KRISTALLOFLEX K 760-80F X-ray generator (Power = 3,000 Westward, Voltage = 20–threescore kV and Intensity = 5–eighty mA) which has an 10-ray tube with copper anode (λ = i.54056 Å). The equipment operated at 40 kV and twoscore mA with 2θ varying from x° to 60° with a stride size of 0.05°.

ii.3. Preparation of TPS Films

Starch films were prepared by the casting technique following the procedure described by Medina-Jaramillo et al. [11]. Briefly, the picture show-forming solution was composed of irish potato, corn, wheat or rice starch (5 wt %), glycerol (1.5 wt %), and distilled water (93.5 wt. %). The solution was stirred at room temperature for 45 min and so heated at 96 °C for 40 min to guarantee complete starch gelatinization. The mixture was and so cooled, degassed under vacuum for 7 min, and finally poured onto Petri dishes (0.34 g/cmii). The plates were dried in an oven with circulating air at 50 °C for 48 h. The dried films were peeled off and stored at room conditions (effectually 25 °C and 50% relative humidity) for a week before characterization.

2.4. Pic Characterization

two.iv.1. Film Thickness

Film thickness was measured in different locations with a Palmer Electronic digital micrometer (Madrid, Espana). The mean value was calculated and used for the rest of the calculations.

2.iv.2. Hydration Properties

The h2o content and solubility in water of the films were determined with samples of 1 × i cm2 following procedures described in the literature with some modifications [iii,11]. Firstly, the h2o content was measured by determining the weight loss of the films after drying in an oven for v h at 110 °C. The measurements were taken in quadruplicate. The quantity of absorbed h2o or wet content was expressed as percentage (grams of h2o in 100 grams of sample) using Equation (1):

where one thousand 0 and one thousand 1 are the mass before and after drying, respectively.

After that, the water solubility of the samples was measured by placing the in a higher place dried films individually in 10 mL tubes filled with ix mL of distilled h2o. The tubes were capped and stored at 25 °C for 24 h, after which the films were taken out and dried again at 110 °C for 5 h in guild to make up one's mind the final mass of dry matter, mf . Water solubility was calculated from the loss of total soluble thing equally follows (Equation (2)):

The solubility values were taken as the average of at least four repetitions.

two.iv.iii. Migration into Nutrient Simulants

Migration studies were carried out following the current legislation [12]. The simulants called were: simulant A, ethanol (ten% five/v, simulating hydrophilic foods); simulant B, acetic acid (iii% w/v, simulating acid foods); and simulant C, isooctane (simulating lipophilic foods with free fats at the surface). Motion-picture show samples were immersed in ix mL of the simulants with a contact ratio of half dozen dmtwo of film per kg of simulant. In accordance with Exam number OM1, the films were left in contact with the food simulants for 10 days at twenty °C, afterward which the samples were withdrawn, stale and weighed. The difference between the initial and final weight corresponds to the mg of the movie components released/dmtwo of contact surface. The tests were run in quadruplicate.

2.4.4. Transparency

The transparency (in terms of opacity) of the films was determined using a basic VIS V-1200 spectrophotometer (VWR, Barcelona, Spain) at a wavelength of 600 nm following the procedure used by other researchers [1]. The opacity was calculated as shown in Equation (iii):

where ten is the thickness (expressed in mm) of the film and Abs600 is the absorbance measured at 600 nm. Lower values of the opacity parameter, as divers on Equation (ane), imply greater transparency.

2.4.5. Scanning Electron Microscopy (SEM)

The microstructure of the films was observed from SEM images obtained with a Hitachi Scanning Electron Microscope (Hitachi S3000N, Tokyo, Japan) using an accelerating voltage of five kV. The images were taken on the surface and in cross sections of all the studied films. Stale sheet samples were cryofractured after immersion in liquid nitrogen. Before the assay, the samples were coated with gold for amend observation.

2.4.six. Atomic Force Microscopy (AFM)

Film surfaces were also analyzed by an NT-DMT Atomic Force Microscope (NTEGRA Prima model, Moscow, Russia) operating in tapping mode. The images were processed using the software Nova Px (NT-MDT Co., Moscow, Russian federation, 2013) and three-dimensional images of the film surfaces (10 µm × 10 µm) were obtained.

two.4.vii. Mechanical Properties

The mechanical tensile properties of the films were adamant with an Instron 3344 Universal Test instrument (Norwood, MA, U.s.a.) equipped with 2000 Due north load cell and operated at 25 mm/min following ASTM D882-12 (2012) [xiii] standard recommendations. The samples were cut into dumbbell-shaped specimens. Mechanical properties of each film were calculated using the average thickness of the specimen and at least five specimens per sample were tested. The tensile properties studied were tensile strength at break, elongation at pause, and Young'south modulus.

2.4.8. X-ray Diffraction (XRD) Studies

Moving picture diffractograms were recorded on a Bruker diffractometer (D8-Accelerate model, Ettlingen, Frg) equipped with a KRISTALLOFLEX K 760-80F X-ray generator. The equipment operated at forty kV and forty mA, with 2θ varying from 10° to sixty° with a footstep size of 0.05°. The FITYK software (0.9.eight version, Warsaw, Poland) was used for bend plumbing equipment.

3. Results and Word

3.1. Starch Label

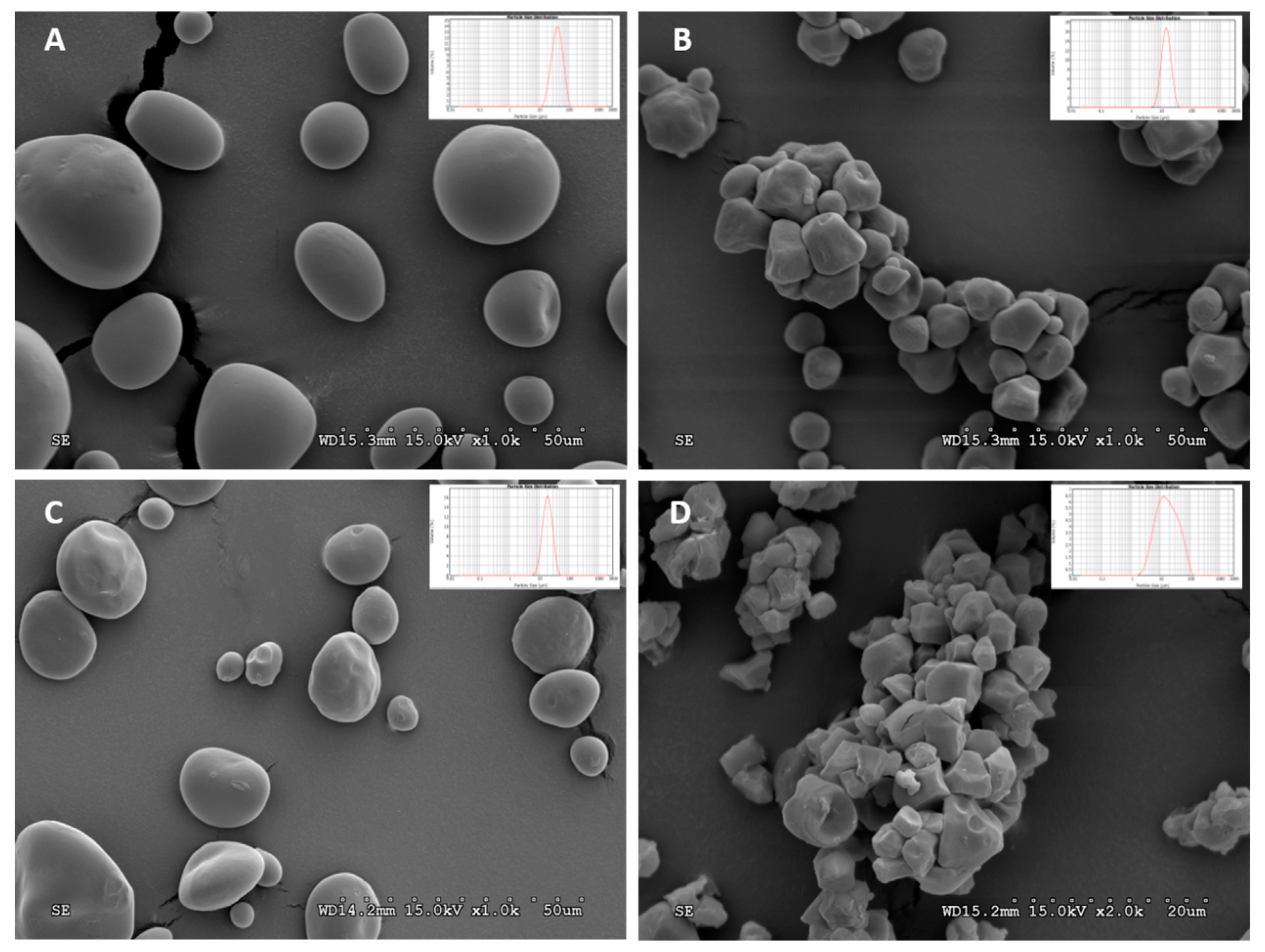

Figure ane shows the SEM micrographs of the starch granules obtained from four sources: spud, corn, wheat, and rice. The granule shape is profoundly influenced by the starch source, as previously reported [14]. Potato starch granules have an oval shape, corn and rice starch granules accept a polyhedral shape, and wheat starch granules accept a lenticular shape. Their general appearance is like to that previously mentioned by other researchers [8,14,fifteen,16]. The micrographs point to unlike size distributions, every bit confirmed by light amplification by stimulated emission of radiation diffraction measurements.

Starch granule size was determined past laser diffraction and the results are shown on Table ane. Tater starch presented the highest grain size ranging from 24 to 73 µm. Corn and wheat starches presented similar average diameters and size distributions ranging from 10 to 24 µm and 12 to 31 µm, respectively. Particle size analysis of rice starch ranged from 5 to 52 µm and showed wider size dispersion, every bit tin can be deduced from the college bridge value and standard deviations. The average diameter of the starch grains was 46.02, 16.38, 20.75, and 23.30 µm for potato, corn, wheat, and rice, respectively. These results are in good agreement with those obtained by SEM, which pointed to the higher average bore of tater starch grains with respect to others. In improver, rice starch seems to have a wider size distribution and great agglomerations of grains, which might explain the higher span value constitute.

The amylose content of the starches was similar for all the starches although with slight differences. These differences could have sure influence on the unlike backdrop obtained for the films, as it will be discussed afterwards. In order, the amylose content of the starches was the following: rice (16.9%) < irish potato (20.5%) < wheat (24.5%) ≈ corn (24.eight%). The literature reports considerable discrepancies in the amylose content of starches, mainly due to the verbal botanical origin of each starch and the conclusion method. Nevertheless, the amylose content of the starches we recorded and the values presented in the literature were in practiced understanding [9,17,eighteen,19].

In dissimilarity to amylose content, the values of weight-average molecular weight of the studied starches have shown significant differences. We found that the molecular weight of rice starch is the highest reaching a value of 83.2 MDa. Potato starch presents an intermediate value (69.5 MDa) and corn and wheat starches have like and the lowest values (≈51 MDa). The origin of these values could be in the molecular weight of the two macromolecular constituents of starch, amylose, and amylopectin. Every bit stated in the Introduction Section, amylose is a linear polysaccharide with an average molecular mass of 105 g·mol−1 and amylopectin is a branched polysaccharide with an boilerplate molecular mass of x6–tenseven g·mol−1. For this reason, starches with high amylose content could presumably have lower molecular weight and a relatively more linear structure than those with a high content of amylopectin.

The amount of phosphate monoesters contained in starch is ordinarily very low and depends on plant origin. Generally, murphy starch contains a higher phosphate monoester quantity than cereal starches [twenty,21]. As expected, in this work the phosphorus content of tater starch was the highest as tin can be seen in Materials Section. In starch, the phosphorus is present in the form of phosphate monoester [22]. Therefore, potato starch contains the highest value of phosphate monoester.

With respect to the moisture content of the starches (adamant by a gravimetric method), the most hygroscopic starch was that obtained from potato, which reached values of around 15%, while the other starches showed similar values of around 9–11%. This difference could be related to the fact that irish potato starch is more phosphorylated and hence has a significant higher hydration capacity [23]. All the values are in proficient agreement with those reported in the literature [8,fourteen].

3.2. Characterization of Starch-Based Films

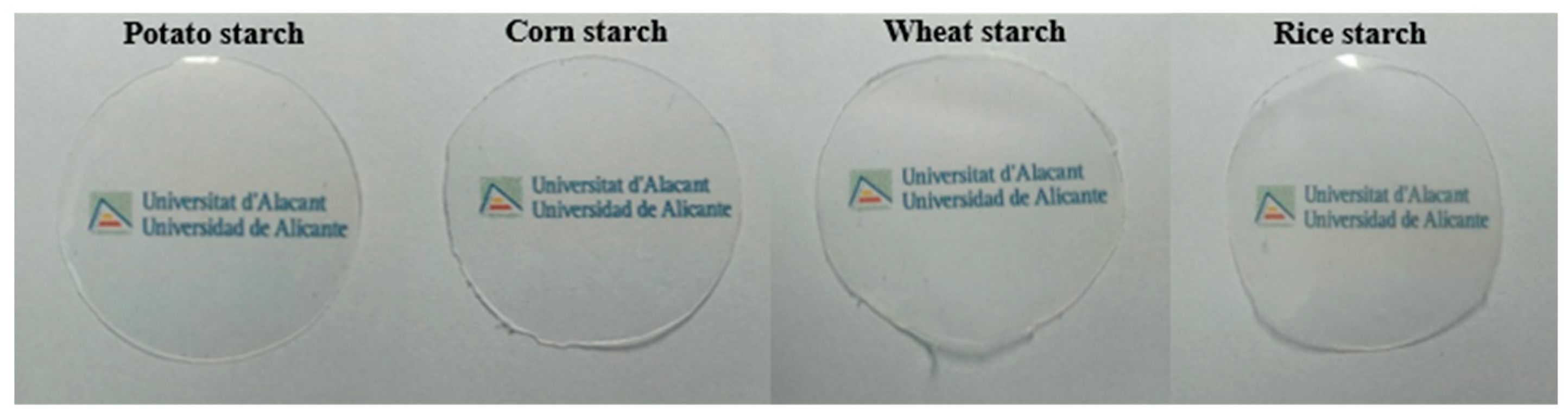

Effigy two shows the visual advent of the TPS-based films synthesized from potato, corn, wheat, and rice. At a macroscopic calibration, all the films were transparent, homogeneous, and like shooting fish in a barrel to handle. The thickness of the films ranged between 0.183 and 0.222 mm (meet Table ii). As can be observed, the standard divergence values for the thickness were minor, underlining the uniformity of the films obtained.

3.ii.1. Hydration Backdrop

Table 2 shows the results obtained for the water content and water solubility of the films. With regard to the application of the synthesized films for food packaging, water content of the films is of considerable importance because both starch and food are highly hygroscopic. In improver, water acts as a plasticizer of starch so the presence of water molecules in films could alter their properties [24]. The films obtained from wheat and rice starch showed similar water content values of ~12%. Potato starch had a slightly college h2o content (~xiv%) and corn starch had the lowest value. The h2o content of the obtained films was considerably lower than the values reported by Basiak et al. [9] and Luchese et al. [8,14], and could represent an interesting advantage for applications involving foodstuffs.

The degree of water solubility of biodegradable films made from water-sensitive biopolymers such as starch is a key parameter, and water solubility is closely related to biodegradability [25]. Water insolubility may be useful for specific applications of films, such as the manufacture of biodegradable packaging, ensuring, among other things, product integrity and water resistance [9], although, for example, edible films for candies crave a high caste of h2o solubility [26]. As shown in Tabular array two, the water solubility values of the films were around 28–32% for all the samples, which is similar or even lower than the values found in the literature [14,27]. In all cases, the films showed great integrity until the finish of the solubility tests. Based on these findings, then, information technology can be inferred that neither parameter—h2o content or solubility in water—is greatly influenced past the starch granule composition or molecular weight of the starch.

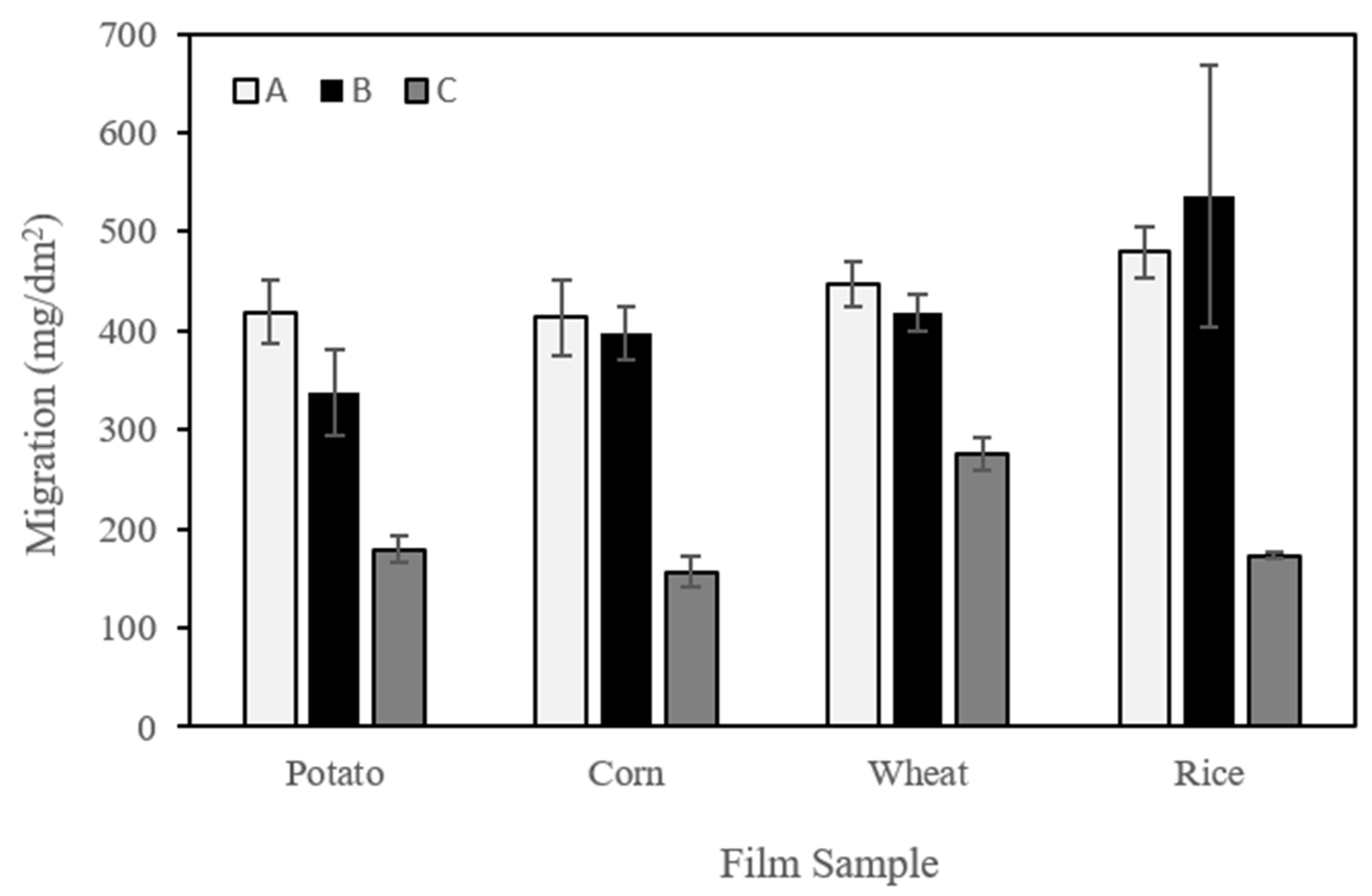

3.2.ii. Migration into Food Simulants

Figure three shows the mean values obtained for the overall migration of the films into food simulants. In our experiment, ethanol 10% v/5 (simulant A) imitation hydrophilic food, acetic acrid 3% westward/v (simulant B) acrid hydrophilic nutrient (pH under 4.v), and isooctane (simulant C) lipophilic food with complimentary fats at the surface. The three simulants called present different polarities, and, in all cases migration. Hence solubility of the components was considerably greater when they were immersed in the hydrophilic simulants (simulants A and B). These results are in expert agreement with above mentioned water solubility results since all the films were of a highly hydrophilic nature. Like results were besides obtained in a previous work on corn starch films [28]. A comparison of the films obtained from the different starch sources suggests that there are no significant differences in terms of their migration behavior.

3.2.3. Transparency

Transparency is a key parameter for films since they are primarily used for food packaging, and a loftier degree of transparency is usually related to its acceptability every bit packaging material because of the better visual presentation of the food [26]. Notwithstanding, different degrees of pic transparency may be also useful, depending on the specific application. For example, materials with depression transparency may aid increase the shelf life of some packaged products, and highly transparent films tin can reduce antimicrobial activity [29]. The transparency results obtained in our experiment are shown on Tabular array 2. Similar or lower transparency values were constitute by Hornung et al. [three]. The potato starch picture was considerably more transparent than the balance of the films, while the corn starch pic was the least transparent. The same decision was reached by Basiak et al. [ix] and Dai et al. [10]. This lower transparency of corn starch films might exist due to the high lipid content and xanthous color of corn starch as a result of the presence of small quantities of impurities or pigments [9]. In addition, Hizuruki [30] reported that cereal starches usually contain more short bondage and fewer long bondage in the amylopectin branches than tuber starches. For this reason, we can assume that amylopectin in potato starch contains a high number of long chains which could contribute to a worst reordering of the chains and the formation of a less compact and hence more transparent starch matrix [19]. In whatever case, a certain degree of opacity may be suitable for applications in which protection against incident light is important; for example, for wrapping products which can be degraded by light-catalyzed reactions [31]. Yet, at macroscopic scale, these differences in transparency are virtually negligible, as can be seen from Figure 2, so the divergence in transparency would not affect to the general use of a given type of starch to obtain biodegradable starch films.

3.two.4. Scanning Electron Microscopy (SEM)

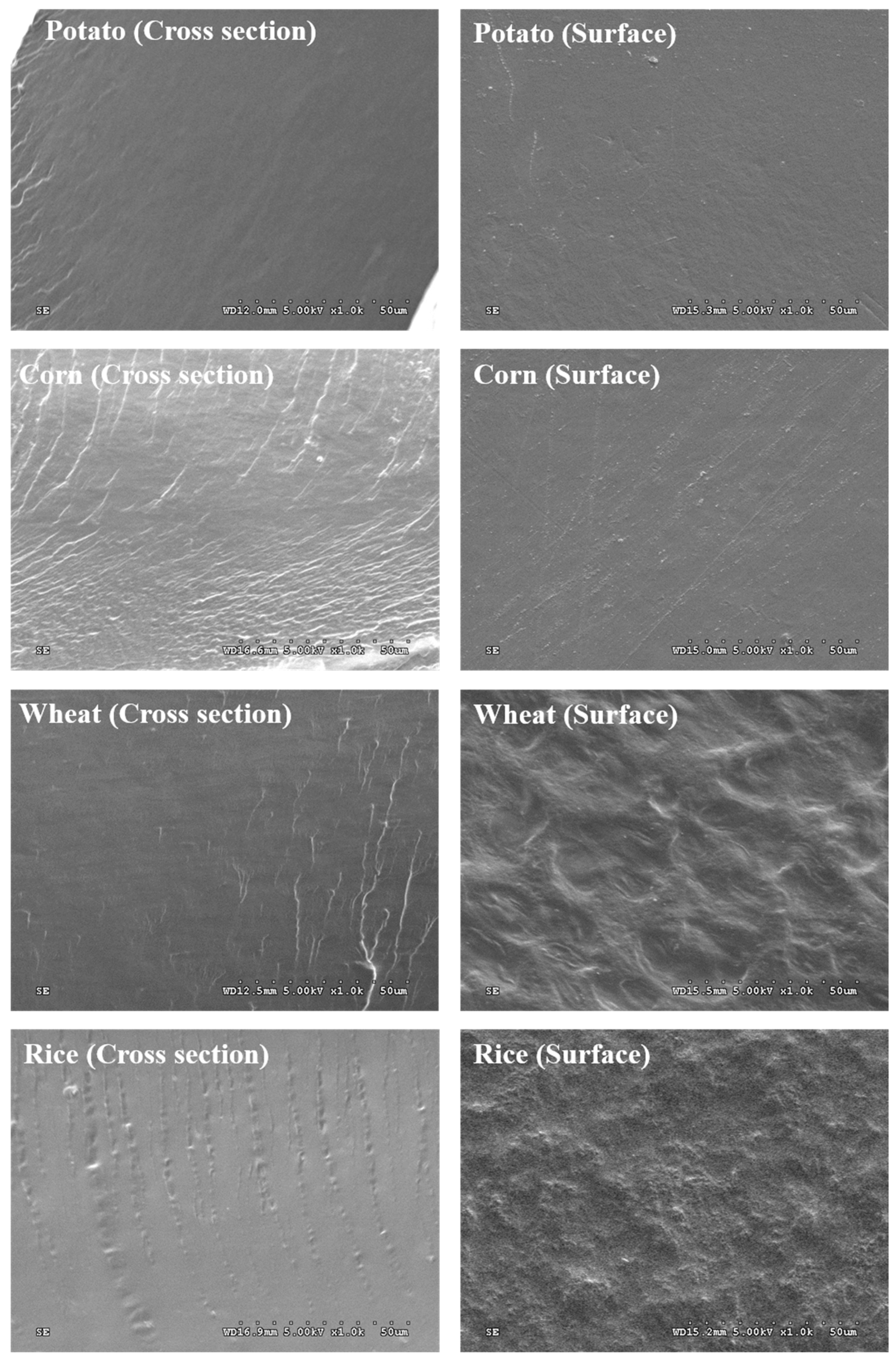

SEM micrographs of the TPS matrix provide interesting data near the microstructure of the obtained films in terms of their homogeneity, layer structure, pores and cracks, and surface smoothness [32]. SEM micrographs of film cross sections and surfaces can be seen in Figure 4. The cross section images for all the starches point to a homogeneous internal structure without pores, reflecting a good starch gelatinization process and the disruption of all the starch granules, as observed past other researchers [7,11]. The absence of defects in the matrix and on the film surface is indicative of the structural integrity of the matrix, which could explain the better tensile strength of the obtained films compared with the findings of previous works, every bit volition be discussed later. It would also explain the expert transparency results obtained, along the lines mentioned by Hosseini et al. [33].

iii.2.5. Atomic Force Microscopy (AFM)

AFM helps to understand the surface morphology and homogeneity of films by ways of a topographic report based on the atomic interaction between constituents [34]. This technique provides qualitative (morphology) data of the studied films. Figure 5 shows tri- and bi-dimensional topographic AFM images of the films, which contribute to the characterization of their surface, and bi-dimensional contrast phase AFM images, which provide information about the beingness or absence of phases with different mechanical properties. In our case, the technique allows the identification of the remains of unplasticized starch. Effigy v points to two different types of behavior. The AFM images of the films obtained from potato, corn and rice starch pointed to a surface with rounded and not-homogeneously dispersed peaks, whereas the topography of the films obtained from wheat starch showed a more homogeneous distribution of sharper peaks. Two-dimensional (second)-contrast Phase images can contribute to understanding the caste of plasticization of the different films through the ascertainment of darker and lighter regions in the z-axis. As expected from the SEM results, all films were very homogeneous without big granule structures. The presence of unplasticized starch in all the starch films was almost missing and the size of the isolated ghost granules observed was much lower than that of the starch grains, indicating the not bad capacity of glycerol to act as starch plasticizer. Even in the case of spud starch films, which showed a more pronounced presence of starch rests, these granules were less than 2% of the size of the native potato starch grains, pointing to a high degree of plasticization. The small amount of ghost granules observed past AFM could be responsible for the pocket-sized crystalline diffraction peaks obtained past the XRD analyses, equally volition exist discussed subsequently.

3.two.6. X-ray Diffraction (XRD) Studies

XRD was used to investigate the crystal structure of the films obtained. The crystalline organization of native starch was seen to be strongly influenced past its botanical origin. Cereal starches such as corn, wheat, or rice starch, typically nowadays an A-type crystal structure, while a B-blazon structure is characteristic of tuber starches such equally irish potato starch [eight,35,36]. Figure half dozen shows the XRD patterns of the studied starches and the developed TPS films. On the one paw, native starches from cereals (corn, wheat and rice) showed a very similar pattern, with XRD peaks at 2θ values of 12.2°, 15.1°, 17°, xviii.one°, 20°, 23.ane°, and 26.vi°, indicating A-type crystallinity every bit previously reported [viii,14,35]. On the other hand, spud starch (tuber origin) showed B-blazon crystallinity, with XRD peaks at 2θ values of v.5°, 11.one°, 15.1°, 17.1°, 19.7°, 22.iii°, 24.ane°, and 26.3°, which are in good understanding with the values reported in the literature [8,17,37].

A loss of crystallinity was expected after the plasticization procedure to obtain starch films due to disruption of the intermolecular hydrogen bonding between starch molecules past the glycerol molecules, which increases the chain mobility of the starch molecules [38]. A comparison of the XRD patterns of the native starches and of those of the corresponding films confirmed the neat loss of crystallinity afterwards the plasticization process. The absence of intense and well-defined peaks in all the diffractograms of the obtained films and the broad hump centered at 2θ = nineteen.6–xix.8° underlined the severe decrease in the crystalline structure of the starch granule and the of import contribution of the new amorphous phase [17,39]. These observations confirm that the glycerol used as plasticizer achieved the loss of the starch grain construction and successfully hindered the retrogradation procedure of the starch molecules, thereby preventing hydrogen bonding between the polymer bondage [3]. Yet, some modest and undefined diffraction peaks centered at 2θ angles around 17, 20, 21.5, and 22° were observed, indicating that some crystallinity remained. These findings are similar to those recently published in the literature [3,8,35]. In order to study the above mentioned crystalline regions in the final films obtained, the diffractograms were deconvoluted past a Lorentzian fitting function centered on the 4 peaks after subtracting their baseline following the procedure described in López-Rubio et al. [40]. The results constitute for the XRD peaks and the widths at centre superlative peak are shown on Effigy seven and Table 3. The tiptop located at around 2θ = 17–17.4° is due to the existence of small-scale regions of residuum A-blazon or B-type crystallinity in the films [35,xl]. On the other hand, the peaks centered at about 2θ = nineteen.6–19.viii° and 2θ = 22.i–22.seven° are characteristic of a V-blazon crystalline construction and appear after the starch plasticization procedure. This terminal construction consists of six-fold single helices of the amylose-glycerol complex [17]. The height at 2θ

21.five° has been described in the literature as being indicative of the dehydration of the V-type crystallinity [17].

Comparison the XRD spectra of corn, wheat, and rice starch films (Figure 7 and Table iii) leads u.s.a. to conclude that they follow the same pattern, with modest differences in the intensity and full widths at half maximum of the peaks located at 17° and 22°. It tin can be seen in Figure 7 that corn and wheat starch films present a like crystallographic spectrum due to the corresponding starches showroom a relatively similar construction in terms of amylose content and molecular weight. The rice starch films showed the least intense merely widest peaks, which suggest that they are the most amorphous. Therefore, these results suggest that rice starch films are the nigh plasticized considering the peak at 2θ = 17°, which is representative of the remainder unplasticized starch, is less intense than that of the wheat and corn starch films, and the postplasticization peaks (2θ = 20° and 22°) are besides the least defined and intense. This is probably due to rice starch having the highest molecular weight, which lead to a lower crystallization power of the polymer, because the rearrangement of the starch chains could be hindered by its size. Similar conclusions were previously constitute with other polymers [41,42]. Another reason could be found in the amylose content of rice starch, which is the lowest in this report. Rindlav-Westling et al. [43] claimed that, for synthetic polymers, it is known that a linear polymer crystallizes more easily than a branched polymer based on the same monomer. The aforementioned caption could be extrapolated to amylose, with a linear structure, and amylopectin, with a branched structure, finding that films from starches with a lower amylose content could take less crystalline regions. As will be shown after, these observations were in great consonance with the assay of the mechanical backdrop. More amorphous starch films, such as rice starch films, have lower tensile strength and Young's modulus, and higher elongation at break because of their greater mobility [3,44,45]. Like results were reported in other studies [iii,46].

In the case of the potato starch film (the only 1 obtained from a tuber), the films presented an intermediate crystalline structure between rice starch films and those made from corn and wheat starch with undefined broad peaks. This is probably due to potato starch having an intermediate molecular weight and amylose content. In addition, every bit information technology was previously mentioned, white potato starch contains the highest percent of phosphate monoesters. This could also contribute to the more amorphous nature of potato starch films compared to corn and wheat starch films. Phosphate monoesters are charged groups, which tin hinder the starch rearrangement during starch moving picture preparation reducing the ordered or crystal structures of potato starch films. This corroborates the mechanical backdrop observed for the potato starch films, which are less resistant and more stretchable than corn and wheat starch films, and more than resistant and less extensible than rice starch films.

3.ii.7. Mechanical Properties

Determining the tensile backdrop of biodegradable films is necessary to ostend their suitability for future applications, for case, in the food packaging field. These properties can exist afflicted by molecular weight and amylose content of starch, picture thickness, polymer concatenation packing, chain interaction, and crystallinity of the film [10,47]. Values of the mechanical backdrop (maximum tensile force, elongation at break and Young'south modulus) for the studied films are shown in Effigy viii. Maximum tensile strength varied from iv.48 to 8.14 MPa, elongation at break from 35.41 to 100.34%, and Young's modulus from 116.42 to 294.98 MPa. The differing amylose contents clearly affect the mechanical beliefs of the films [48,49]. It is known that amylose forms stronger films than amylopectin [50]. As mentioned above, the amylose content found was in the post-obit gild: rice (sixteen.9%) < murphy (20.5%) < wheat (24.5%) ≈ corn (24.8%). Figure 8 shows that, in general terms, the lowest amylose content, the lowest maximum tensile strength, and stiffness but the highest film stretchability. It can exist seen that wheat and corn starch films, which have like and the highest amylose content, presented similar tensile properties and were more resistant at intermission and less stretchable than murphy and rice starch films. These results may be due to the fact that starch films obtained from high amylose content starch usually have bigger crystalline domains [51], leading to greater mechanical resistance compared to films made from starch with a lower amylose content [38]. These crystalline domains are embedded in the amorphous matrix and could human activity equally reinforcements for improving the film'due south mechanical properties. Every bit explained before, the film'southward crystallinity is also related to the starch molecular weight. Higher starch molecular weights tin hinder the crystallization process by the chain size. Therefore, the higher the amylose content and molecular weight of starch, the higher the crystallinity of the films and hence the higher the tensile strength and Young'southward modulus and the lower the elongation at intermission of the starch moving picture. The same conclusion was reached past Li et al. [52], Cano et al. [48], Muscat et al. [53], and Mali et al. [19]. The values obtained for the mechanical properties of the films studied in this work are similar or much ameliorate (in some cases) than those reported in previous works [8,9,10,14,38,48,54]. Films obtained from the four starch sources showed tensile properties comparable to other mutual polymers currently used for food packaging such as LDPE [14,55].

4. Conclusions

Starch films from 4 botanical sources were prepared past the casting technique. The starch granule composition and molecular weight were seen to accept a significant influence on several physical and chemical properties of the films developed. The amylose content and molecular weight of the starches strongly affected the mechanical properties of the films, which were more than resistant and less extensible when their amylose content and molecular weight were higher and lower, respectively. This is probably due to the fact that the films obtained from starches with a high amylose content usually present a college quantity of crystalline domains, which are presumably responsible for improving the mechanical beliefs of the TPS films. The analysis of the mechanical properties measured reveals that all the films take properties comparable to those of some conventional polymers such as LDPE, underlining the great potential of starch to replace constructed and not-biodegradable plastics in film manufacturing.

Writer Contributions

Conceptualization, J.C.K.-Q. and I.M.-K.; methodology, D.D.-L. and M.Thousand.M.; validation, M.G.Thousand.; formal assay, D.D.-L. and One thousand.G.M.; investigation, D.D.-L.; resource, D.D.-L.; writing—original draft preparation, M.G.M.; writing—review and editing, J.C.Yard.-Q., I.1000.1000. and M.G.M.; visualization, D.D.-L and Chiliad.Chiliad.M.; supervision, J.C.Chiliad.-Q. and I.M.G.; projection administration, J.C.G.-Q. and I.M.-G.; funding acquisition, I.M.-G. and J.C.K.-Q.

Funding

This work was partially supported past the European Commission (FEDER/ERDF), the Spanish MINECO (Ref. CTQ2016-78246-R), and Generalitat Valenciana (Project PROMETEOII/2014/007). M.Thou.Grand. acknowledges support from MINECO (Juan de la Cierva-Formación contract, Ref. FJCI-2016-28081).

Acknowledgments

Nosotros wish to give thanks Gloria Víllora (University of Murcia, Spain) for the starch grains' size measurements by laser diffraction.

Conflicts of Involvement

The authors declare no conflict of involvement. The funders had no role in the design of the report; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Luchese, C.L.; Garrido, T.; Spada, J.C.; Tessaro, I.C.; de la Caba, K. Evolution and label of cassava starch films incorporated with huckleberry pomace. Int. J. Biol. Macromol. 2018, 106, 834–839. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Mo, X.; Pang, J.; Yang, F. Effects of silica on the morphology, structure, and properties of thermoplastic cassava starch/poly(vinyl alcohol) blends. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Hornung, P.South.; Ávila, S.; Masisi, One thousand.; Malunga, L.N.; Lazzarotto, M.; Schnitzler, Eastward.; Ribani, R.H.; Beta, T. Green Development of Biodegradable Films Based on Native Yam (Dioscoreaceae) Starch Mixtures. Starch-Stärke 2018, lxx, 1700234. [Google Scholar] [CrossRef]

- Oliveira, A.5.; da Silva, A.P.Grand.; Barros, Yard.O.; de sá, Grand.; Souza Filho, M.; Rosa, G.F.; Azeredo, H.Grand.C. Nanocomposite Films from Mango Kernel or Corn Starch with Starch Nanocrystals. Starch-Stärke 2018, 70, 1800028. [Google Scholar] [CrossRef]

- Domene-López, D.; Guillén, Grand.M.; Martin-Gullon, I.; García-Quesada, J.C.; Montalbán, M.G. Study of the behavior of biodegradable starch/polyvinyl booze/rosin blends. Carbohydr. Polym. 2018, 202, 299–305. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Nogueira, M.F.; Fakhouri, F.M.; de Oliveira, R.A. Extraction and characterization of arrowroot (Maranta arundinaceae L.) starch and its awarding in edible films. Carbohydr. Polym. 2018, 186, 64–72. [Google Scholar] [CrossRef] [PubMed]

- Cano, A.; Fortunati, E.; Cháfer, Grand.; Kenny, J.Thousand.; Chiralt, A.; González-Martínez, C. Properties and ageing behaviour of pea starch films as affected by blend with poly(vinyl alcohol). Food Hydrocoll. 2015, 48, 84–93. [Google Scholar] [CrossRef]

- Luchese, C.Fifty.; Benelli, P.; Spada, J.C.; Tessaro, I.C. Impact of the starch source on the physicochemical backdrop and biodegradability of unlike starch-based films. J. Appl. Polym. Sci. 2018, 135, 46564. [Google Scholar] [CrossRef]

- Basiak, E.; Lenart, A.; Debeaufort, F. Issue of starch type on the physico-chemical properties of edible films. Int. J. Biol. Macromol. 2017, 98, 348–356. [Google Scholar] [CrossRef] [PubMed]

- Dai, L.; Zhang, J.; Cheng, F. Furnishings of starches from dissimilar botanical sources and modification methods on physicochemical properties of starch-based edible films. Int. J. Biol. Macromol. 2019, 132, 897–905. [Google Scholar] [CrossRef]

- Medina-Jaramillo, C.; Ochoa-Yepes, O.; Bernal, C.; Famá, L. Active and smart biodegradable packaging based on starch and natural extracts. Carbohydr. Polym. 2017, 176, 187–194. [Google Scholar] [CrossRef]

- Commission Regulation. Commission Regulation (European union) No. 10/2011 of 14 Jan 2011 on plastic materials and manufactures intended to come up into contact with nutrient. Off J. Eur. Union 2011, 12, ane–89. [Google Scholar]

- ASTM D882-12 Standard Examination Method for Tensile Properties of Thin Plastic Sheeting; ASTM International: Westward Conshohocken, PA, USA, 2012; Bachelor online: https://www.astm.org/DATABASE.CART/HISTORICAL/D882-02.htm (accessed on 28 March 2018).

- Luchese, C.50.; Spada, J.C.; Tessaro, I.C. Starch content affects physicochemical properties of corn and cassava starch-based films. Ind. Crop. Prod. 2017, 109, 619–626. [Google Scholar] [CrossRef]

- Desse, M.; Fraiseau, D.; Mitchell, J.; Budtova, T. Individual bloated starch granules under mechanical stress: Testify for deformation and book loss. Soft Matter 2010, 6, 363–369. [Google Scholar] [CrossRef]

- Deladino, Fifty.; Teixeira, A.Southward.; Navarro, A.S.; Alvarez, I.; Molina-García, A.D.; Martino, 1000. Corn starch systems every bit carriers for yerba mate (Ilex paraguariensis) antioxidants. Food Bioprod. Process. 2015, 94, 463–472. [Google Scholar] [CrossRef]

- Malmir, S.; Montero, B.; Rico, Thousand.; Barral, 50.; Bouza, R.; Farrag, Y. Effects of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) microparticles on morphological, mechanical, thermal, and barrier properties in thermoplastic irish potato starch films. Carbohydr. Polym. 2018, 194, 357–364. [Google Scholar] [CrossRef] [PubMed]

- Shi, R.; Zhu, A.; Chen, D.; Jiang, X.; Xu, 10.; Zhang, L.; Tian, W. In vitro deposition of starch/PVA films and biocompatibility evaluation. J. Appl. Polym. Sci. 2010, 115, 346–357. [Google Scholar] [CrossRef]

- Mali, S.; Karam, 50.B.; Ramos, Fifty.P.; Grossmann, One thousand.V.Due east. Relationships among the Composition and Physicochemical Properties of Starches with the Characteristics of Their Films. J. Agric. Nutrient Chem. 2004, 52, 7720–7725. [Google Scholar] [CrossRef]

- Blennow, A.; Engelsen, S.B. Helix-breaking news: Fighting crystalline starch energy deposits in the cell. Trends Plant Sci. 2010, 15, 236–240. [Google Scholar] [CrossRef] [PubMed]

- Wickramasinghe, H.A.M.; Blennow, A.; Noda, T. Physico-chemical and degradative backdrop of in-planta re-structured potato starch. Carbohydr. Polym. 2009, 77, 118–124. [Google Scholar] [CrossRef]

- Zhang, B.; Zhao, Y.; Li, X.; Zhang, P.; Li, L.; Xie, F.; Chen, L. Furnishings of amylose and phosphate monoester on aggregation structures of heat-moisture treated potato starches. Carbohydr. Polym. 2014, 103, 228–233. [Google Scholar] [CrossRef]

- Blennow, A. Phosphorylation of the Starch Granule. In Starch: Metabolism and Structure; Nakamura, Y., Ed.; Springer Japan: Tokyo, Nihon, 2015; pp. 399–424. ISBN 978-4-431-55495-0. [Google Scholar]

- Lawton, J.West. Consequence of starch type on the properties of starch containing films. Polymers 1996, 29, 203–208. [Google Scholar] [CrossRef]

- Medina Jaramillo, C.; González Seligra, P.; Goyanes, S.; Bernal, C.; Famá, Fifty. Biofilms based on cassava starch containing extract of yerba mate as antioxidant and plasticizer. Starch-Stärke 2015, 67, 780–789. [Google Scholar] [CrossRef]

- Zhong, Y.; Li, Y.; Liang, Westward.; Liu, L.; Li, Due south.; Xue, J.; Guo, D. Comparing of gelatinization method, starch concentration, and plasticizer on physical backdrop of loftier-amylose starch films. J. Food Procedure Eng. 2017, 41, 1–viii. [Google Scholar] [CrossRef]

- Basiak, E.; Lenart, A.; Debeaufort, F. How Glycerol and Water Contents Affect the Structural and Functional Properties of Starch-Based Edible Films. Polymers 2018, x, 412. [Google Scholar] [CrossRef] [PubMed]

- Moreno, O.; Cárdenas, J.; Atarés, Fifty.; Chiralt, A. Influence of starch oxidation on the functionality of starch-gelatin based agile films. Carbohydr. Polym. 2017, 178, 147–158. [Google Scholar] [CrossRef] [PubMed]

- González, K.; Martin, L.; González, A.; Retegi, A.; Eceiza, A.; Gabilondo, N. D-isosorbide and 1,3-propanediol every bit plasticizers for starch-based films: Characterization and aging written report. J. Appl. Polym. Sci. 2017, 134, 44793. [Google Scholar] [CrossRef]

- Hizukuri, South. Relationship between the distribution of the chain length of amylopectin and the crystalline structure of starch granules. Carbohydr. Res. 1985, 141, 295–306. [Google Scholar] [CrossRef]

- Gutiérrez, T.J.; Tapia, K.S.; Pérez, E.; Famá, 50. Edible films based on native and phosphated eighty:20 waxy:normal corn starch. Starch-Stärke 2015, 67, xc–97. [Google Scholar]

- Lopez, O.; Garcia, M.A.; Villar, Thou.A.; Gentili, A.; Rodriguez, Yard.S.; Albertengo, L. Thermo-pinch of biodegradable thermoplastic corn starch films containing chitin and chitosan. LWT-Food Sci. Technol. 2014, 57, 106–115. [Google Scholar] [CrossRef]

- Hosseini, S.F.; Rezaei, M.; Zandi, M.; Ghavi, F.F. Training and functional backdrop of fish gelatin–chitosan alloy edible films. Nutrient Chem. 2013, 136, 1490–1495. [Google Scholar] [CrossRef] [PubMed]

- Monteiro, G.Chiliad.S.; Oliveira, 5.R.Fifty.; Santos, F.Grand.G.; Barros Neto, East.L.; Leite, R.H.50.; Aroucha, E.M.Thou.; Silva, R.R.; Silva, M.Due north.O. Incorporation of bentonite clay in cassava starch films for the reduction of water vapor permeability. Food Res. Int. 2018, 105, 637–644. [Google Scholar] [CrossRef]

- Sreekumar, P.A.; Al-Harthi, M.A.; De, S.K. Studies on compatibility of biodegradable starch/polyvinyl alcohol blends. Polym. Eng. Sci. 2012, 52, 2167–2172. [Google Scholar] [CrossRef]

- Hulleman, Due south.H.; Kalisvaart, M.; Janssen, F.H.; Feil, H.; Vliegenthart, J.F. Origins of B-blazon crystallinity in glycerol-plasticised, pinch-moulded potato starches. Carbohydr. Polym. 1999, 39, 351–360. [Google Scholar] [CrossRef]

- Morales, Northward.J.; Candal, R.; Famá, L.; Goyanes, S.; Rubiolo, G.H. Improving the physical properties of starch using a new kind of water dispersible nano-hybrid reinforcement. Carbohydr. Polym. 2015, 127, 291–299. [Google Scholar] [CrossRef]

- Phetwarotai, W.; Potiyaraj, P.; Aht-Ong, D. Characteristics of biodegradable polylactide/gelatinized starch films: Effects of starch, plasticizer, and compatibilizer. J. Appl. Polym. Sci. 2012, 126, E162–E172. [Google Scholar] [CrossRef]

- Angellier, H.; Molina-Boisseau, Due south.; Dole, P.; Dufresne, A. Thermoplastic Starch−Waxy Maize Starch Nanocrystals Nanocomposites. Biomacromolecules 2006, 7, 531–539. [Google Scholar] [CrossRef]

- Lopez-Rubio, A.; Flanagan, B.M.; Gilbert, E.P.; Gidley, K.J. A novel approach for calculating starch crystallinity and its correlation with double helix content: A combined XRD and NMR study. Biopolymers 2008, 89, 761–768. [Google Scholar] [CrossRef] [PubMed]

- Chen, 10.; Hou, G.; Chen, Y.; Yang, G.; Dong, Y.; Zhou, H. Consequence of molecular weight on crystallization, melting behavior and morphology of poly (trimethylene terephalate). Polym. Exam. 2007, 26, 144–153. [Google Scholar] [CrossRef]

- Bhagabati, P.; Hazarika, D.; Katiyar, Five. Tailor-made ultra-crystalline, high molecular weight poly(ε-caprolactone) films with improved oxygen gas barrier and optical properties: A facile and scalable approach. Int. J. Biol. Macromol. 2019, 124, 1040–1052. [Google Scholar] [CrossRef]

- Rindlav-Westling, A.; Stading, K.; Hermansson, A.-Thou.; Gatenholm, P. Structure, mechanical and barrier properties of amylose and amylopectin films. Carbohydr. Polym. 1998, 36, 217–224. [Google Scholar] [CrossRef]

- Velasquez, D.; Pavon-Djavid, Thousand.; Chaunier, L.; Meddahi-Pellé, A.; Lourdin, D. Effect of crystallinity and plasticizer on mechanical properties and tissue integration of starch-based materials from two botanical origins. Carbohydr. Polym. 2015, 124, 180–187. [Google Scholar] [CrossRef] [PubMed]

- Xie, F.; Flanagan, B.Grand.; Li, M.; Sangwan, P.; Truss, R.W.; Halley, P.J.; Strounina, Due east.V.; Whittaker, A.K.; Gidley, K.J.; Dean, G.M.; et al. Characteristics of starch-based films plasticised past glycerol and by the ionic liquid 1-ethyl-3-methylimidazolium acetate: A comparative written report. Carbohydr. Polym. 2014, 111, 841–848. [Google Scholar] [CrossRef][Green Version]

- Li, M.; Xie, F.; Hasjim, J.; Witt, T.; Halley, P.J.; Gilbert, R.G. Establishing whether the structural feature controlling the mechanical backdrop of starch films is molecular or crystalline. Carbohydr. Polym. 2015, 117, 262–270. [Google Scholar] [CrossRef]

- Paes, S.South.; Yakimets, I.; Mitchell, J.R. Influence of gelatinization process on functional properties of cassava starch films. Food Hydrocoll. 2008, 22, 788–797. [Google Scholar] [CrossRef]

- Cano, A.; Jiménez, A.; Cháfer, One thousand.; Gónzalez, C.; Chiralt, A. Result of amylose:amylopectin ratio and rice bran addition on starch films properties. Carbohydr. Polym. 2014, 111, 543–555. [Google Scholar] [CrossRef][Green Version]

- Talja, R.A.; Helén, H.; Roos, Y.H.; Jouppila, One thousand. Effect of various polyols and polyol contents on physical and mechanical properties of white potato starch-based films. Carbohydr. Polym. 2007, 67, 288–295. [Google Scholar] [CrossRef]

- Pushpadass, H.A.; Kumar, A.; Jackson, D.S.; Wehling, R.L.; Dumais, J.J.; Hanna, M.A. Macromolecular Changes in Extruded Starch-Films Plasticized with Glycerol, Water and Stearic Acid. Starch-Stärke 2009, 61, 256–266. [Google Scholar] [CrossRef]

- García, Thou.A.; Martino, Yard.N.; Zaritzky, N.E. Microstructural Characterization of Plasticized Starch-Based Films. Starch-Stärke 2000, 52, 118–124. [Google Scholar]

- Li, M.; Liu, P.; Zou, W.; Yu, L.; Xie, F.; Pu, H.; Liu, H.; Chen, L. Extrusion processing and characterization of edible starch films with different amylose contents. J. Food Eng. 2011, 106, 95–101. [Google Scholar] [CrossRef]

- Muscat, D.; Adhikari, B.; Adhikari, R.; Chaudhary, D.S. Comparative written report of flick forming behaviour of depression and high amylose starches using glycerol and xylitol as plasticizers. J. Food Eng. 2012, 109, 189–201. [Google Scholar] [CrossRef]

- Colussi, R.; Zanella Pinto, V.; Lisie, South.; Halal, S.L.Yard.E.; Biduski, B.; Prietto, L.; Castilhos, D.D.; Zavareze, E.R.; Guerra Dias, A.R. Acetylated rice starches films with different levels of amylose: Mechanical, h2o vapor barrier, thermal, and biodegradability properties. Food Chem. 2017, 221, 1614–1620. [Google Scholar] [CrossRef] [PubMed]

- Kormin, S.; Kormin, F.; Beg, M.D.H.; Piah, Yard.B.Grand. Physical and mechanical backdrop of LDPE incorporated with unlike starch sources. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Melaka, Malaysia, 6–7 May 2017; Volume 226, p. 012157. [Google Scholar]

Effigy 1. SEM micrographs of (A) spud starch (1000×), (B) corn starch (m×), (C) wheat starch (500×), and (D) rice starch (2000×). Dissimilar magnifications were used for a clearer observation of the granules. The particle size distribution profiles, equally measured by laser diffraction, are given for each starch.

Figure ane. SEM micrographs of (A) potato starch (1000×), (B) corn starch (thousand×), (C) wheat starch (500×), and (D) rice starch (2000×). Dissimilar magnifications were used for a clearer observation of the granules. The particle size distribution profiles, as measured by laser diffraction, are given for each starch.

Figure ii. Visual aspect of films obtained from potato, corn, wheat, and rice starch.

Figure two. Visual attribute of films obtained from white potato, corn, wheat, and rice starch.

Effigy 3. Overall migration values into different food simulants. (A) Ethanol (10% v/five), (B) acetic acid (iii% w/5), and (C) isooctane.

Effigy 3. Overall migration values into different food simulants. (A) Ethanol (10% v/v), (B) acetic acid (3% w/5), and (C) isooctane.

Figure 4. SEM micrographs of the cross sections and surfaces of tater, corn, wheat and rice starch films (Magnification 1000×).

Figure 4. SEM micrographs of the cross sections and surfaces of white potato, corn, wheat and rice starch films (Magnification 1000×).

Figure 5. AFM 3- and bi-dimensional topographic images and bi-dimensional contrast stage images of the surface of tater, corn, wheat, and rice films.

Figure 5. AFM three- and bi-dimensional topographic images and bi-dimensional contrast phase images of the surface of potato, corn, wheat, and rice films.

Figure vi. XRD of the starch grains and obtained films.

Effigy 6. XRD of the starch grains and obtained films.

Figure seven. Deconvoluted XRD peaks of starch films obtained from potato, corn, wheat, and rice starch using the Lorentz function.

Effigy 7. Deconvoluted XRD peaks of starch films obtained from potato, corn, wheat, and rice starch using the Lorentz office.

Figure 8. Mechanical properties of the starch films studied. (A) Maximum tensile strength; (B) elongation at intermission; and (C) Immature's modulus.

Figure 8. Mechanical properties of the starch films studied. (A) Maximum tensile strength; (B) elongation at break; and (C) Immature'south modulus.

Table ane. Particle size analysis of potato, corn, wheat, and rice starches.

Table 1. Particle size assay of irish potato, corn, wheat, and rice starches.

| Starch | D(0.1) (µm) | D(0.5) (µm) | D(0.nine) (µm) | Average Diameter (µm) | Span |

|---|---|---|---|---|---|

| Potato | 24.fifty ± 0.02 | 42.67 ± 0.04 | 72.58 ± 0.09 | 46.02 ± 0.05 | ane.127 ± 0.001 |

| Corn | 9.76 ± 0.11 | 15.50 ± 0.24 | 24.25 ± 0.92 | 16.38 ± 0.33 | 0.934 ± 0.051 |

| Wheat | 12.17 ± 0.03 | 19.60 ± 0.04 | xxx.96 ± 0.06 | 20.75 ± 0.04 | 0.959 ± 0.001 |

| Rice | 5.49 ± 0.22 | xvi.22 ± 1.56 | 52.32 ± 4.71 | 23.30 ± 2.09 | 2.887 ± 0.013 |

Table 2. Properties of the starch films obtained.

Tabular array two. Backdrop of the starch films obtained.

| Sample Film | Thickness (mm) | H2o Content (%) | H2o Solubility (%) | Opacity (A600/mm) |

|---|---|---|---|---|

| Potato | 0.183 ± 0.014 | 14.40 ± 0.34 | 29.74 ± 0.24 | 0.61 ± 0.06 |

| Corn | 0.216 ± 0.012 | 10.78 ± 0.68 | 27.88 ± 0.58 | ane.56 ± 0.01 |

| Wheat | 0.222 ± 0.009 | 12.65 ± 0.57 | 32.57 ± 2.04 | 0.93 ± 0.07 |

| Rice | 0.211 ± 0.024 | 12.39 ± 0.59 | 32.25 ± 2.74 | 0.90 ± 0.07 |

Table 3. 2θ peaks and their full widths at half maximum for the starch films obtained.

Table 3. 2θ peaks and their full widths at half maximum for the starch films obtained.

| Potato Starch | Corn Starch | Wheat Starch | Rice Starch | |||||

|---|---|---|---|---|---|---|---|---|

| 2θ | Width | 2θ | Width | 2θ | Width | 2θ | Width | |

| Superlative 1 | 17.10 | 1.98 | 17.00 | 1.74 | 17.20 | 2.35 | 17.40 | three.30 |

| Acme 2 | 19.lxx | 3.56 | 19.sixty | three.10 | 19.75 | three.09 | 19.85 | 3.01 |

| Peak three | 21.50 | 0.24 | 21.45 | 0.eighteen | 21.50 | 0.24 | 21.45 | 0.20 |

| Elevation four | 22.75 | 3.38 | 22.05 | 3.76 | 22.threescore | 3.69 | 22.twenty | four.70 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/past/iv.0/).

Why Is Starch A Polymer,

Source: https://www.mdpi.com/2073-4360/11/7/1084/htm

Posted by: galindocurcasiblia.blogspot.com

0 Response to "Why Is Starch A Polymer"

Post a Comment